Famous Best Dry Granulator – HLSG series Mixing Granulator – Chengxiang

Famous Best Dry Granulator – HLSG series Mixing Granulator – Chengxiang Detail:

Working principle

Characters

● With consistent programmed technology ( man-machine interface if option selected ) , the machine can get assured of stability in quality, as well as easy manual operation for convenience of technological parameter and flow progress.

● Adopt frequency speed adjustment to control the stirring blade and cutter, easy to control the size of particle.

● With the rotating shaft hermetically filled with air, it can prevent all dust from compact.

● With a structure of conical hopper tank, all material can be in uniform rotation. The tank is laid with an interlayer on the bottom, in which water cooling circulation system featuring higher thermostatic performance than air cooling system is furnished, which leads to improve the quality of particles.

● With automatic lifting of the pan cover, the tank outlet matching with drying device, self-equipped arm-ladder, it is easy to operate.

● Lifting system with propeller is more beneficial to clean paddles and pot body.

● Mouth of material outlet has changed into arc-shaped, avoiding up dead spaces.

Technical Parameters

|

Model |

HLSG-50 |

HLSG-100 |

HLSG-200 |

HLSG-300 |

|

|

Hopper Volume |

50L |

100L |

200L |

300L |

|

|

Effective Working Capactiy: Material proportion 0.5 g/cu.cm |

12-35L |

25-80L |

60-160L |

80-240L |

|

|

operation time |

Mixing: about 2 mins Granulating: about 7-14 min/batch |

||||

|

Granularity |

φ0.14-φ1.5mm(12 – 100mesh) |

||||

|

Mixing Motor |

5.5KW 6Pole |

7.5KW 6Pole |

15KW 6Pole |

22Kw 6Pole |

|

|

Rotate Speed of Stirring Paddle Frequency Adjusting speed |

30-380R/min |

30-250R/min |

30-250R/min |

20-200R/min |

|

|

Granulating Motor |

1.5KW 2Pole |

3KW 2Pole |

4KW 2Pole |

7.5KW 2Pole |

|

|

Rotate Speed of Granulating Paddle Frequency Adjusting speed |

50-3000R/min |

||||

|

Air Compress |

0.3 stere/min 0.7Mpa (equipped by user.) |

||||

|

Joint of the Cooling Water |

Φ10mm |

||||

|

Joint of the Air Compress |

φ10mm |

||||

|

Height of Charger Outlet |

796mm |

796mm |

920mm |

985mm |

|

|

Overall Dimensions (L×W×H) mm |

1935×662×1575 |

2078×702×1720 |

2180× 810×2100 |

2420x970x2450 |

|

|

Weight |

400kg |

700kg |

1100kg |

1350kg |

|

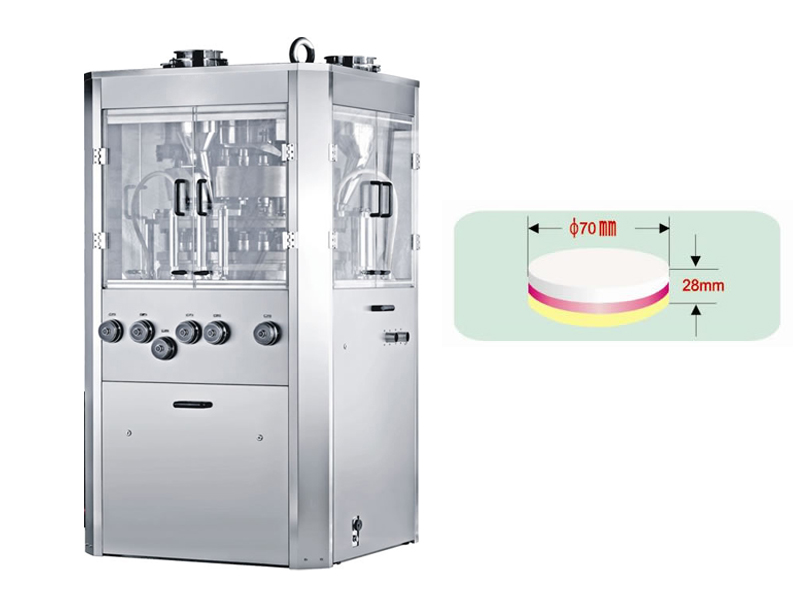

Product detail pictures:

Related Product Guide:

We have probably the most state-of-the-art output equipment, experienced and qualified engineers and workers, recognized good quality manage systems plus a friendly skilled income workforce pre/after-sales support for Famous Best Dry Granulator – HLSG series Mixing Granulator – Chengxiang , The product will supply to all over the world, such as: Saudi Arabia, Sweden, Botswana, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.